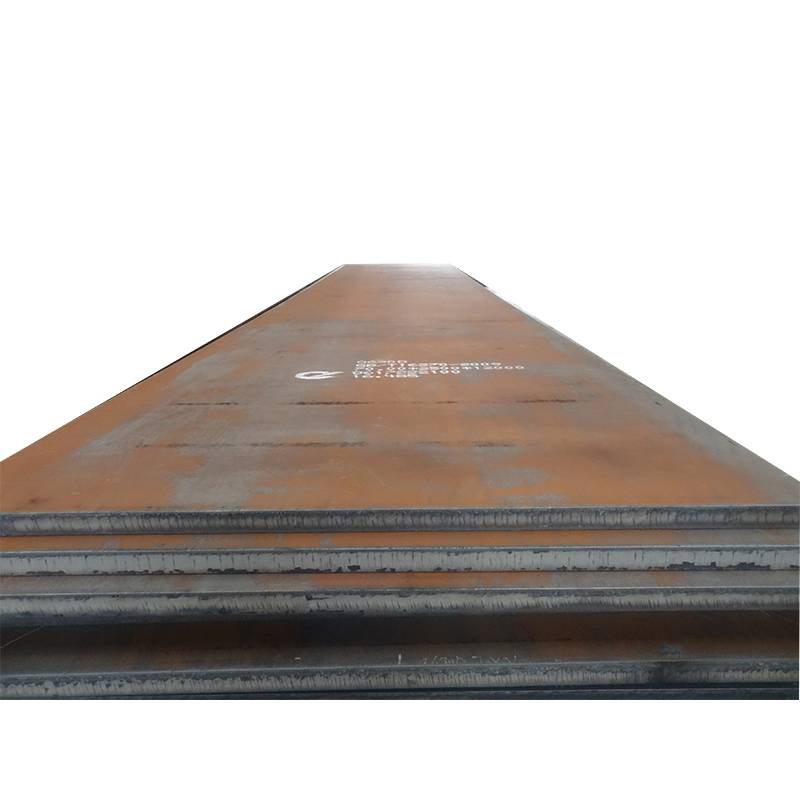

Nxiba i-Resistant Steel Plate

Iipleyiti zetsimbi ezingenakunxitywa zibhekisela kwiimveliso zeplate ezikhethekileyo ezisetyenziswe phantsi kweemeko zokugqoka iindawo ezinkulu.Okwangoku, iipleyiti zentsimbi eziqhele ukunxitywa ziipleyiti ezenziwe ngentsimbi eqhelekileyo enekhabhoni ephantsi okanye intsimbi ephantsi enealloyi enokuqina okuhle kunye neplastikhi ngokubeka i-welding engqindilili ethile ye-alloy engagungqiyo kunye nokuqina okuphezulu kunye nokumelana nokunxiba okugqwesileyo. imveliso.

Ukuqina komphezulu kunokufikelela kwi-HRc58-62

1.

| Umgangatho | IBanga | |

| Cnina | NM360.NM400.NM450,NM500 | |

| Swiden | HARDOX400,HARDOX450.HARDOX500.HARDOX600, SB-50, SB-45 | |

| Jemani

| XAR400.XAR450, XAR500, XAR600, Dilidlur400, illidur500 | |

| Bheljiyam | QUARD400, QUARD450.QUARDS00 | |

| Fransi | FORA400.FORA500, Creusabro4800.Creusabro8000 | |

| Finlend: | RAEX400, RAEX450, RAEX500 | |

| Japhan | JFE-EH360,JFE - EH400,JFE - EH500,WEL-HARD400, WEL-HARD500 | |

| I-MN13 Ipleyiti yentsimbi ekwazi ukumelana nokunxitywa kwemanganese ephezulu:Umxholo wemanganese yi-130%, emalunga namaxesha ali-10 entsimbi eqhelekileyo engagugiyo, kwaye ixabiso liphezulu. | ||

| Iinkcukacha zobungakanani(mm) | ||

| Ukutyeba | 3-250mmUbungakanani obuqhelekileyo: 8/10/12/14/16/18/20/25/30/40/50/60 | |

| ububanzi | 1050-2500mm Ubungakanani obuqhelekileyo: 2000/2200mm | |

| ubude | 3000-12000mm Ubungakanani obuqhelekileyo: 8000/10000/12000

| |

2.Ipleyiti edityanisiweyo engagugiyo:

Yimveliso yepleyiti eyenziwe ngokujonga ubukhulu obuthile bomaleko ongagugiyo kunye nobunzima obuphezulu kunye nokumelana okugqwesileyo kokunxiba kumphezulu wentsimbi yekhabhoni ephantsi okanye intsimbi ephantsi yealloy enokuqina okuhle kunye neplastiki.I-anti-wear layer ithatha i-1 / 3-1 / 2 yobukhulu obupheleleyo.

l Uluhlu olungagungqiyo lwenziwe ikakhulu nge-chromium alloy, kunye nezinye izinto ze-alloy ezifana ne-manganese, i-molybdenum, i-niobium, kunye ne-nickel nazo zongezwa.

| IBanga | :3+3,4+2,5+3,5+4,6+4,6+5,6+6,8+4,8+5,8+6,10+5,10+6,10 +8, 10+10,20+20 |

3.Iinkonzo ezikhoyo

Iipleyiti ezixhathisayo ziyakwazi ukubonelela ngeendlela zokucutshungulwa: iindawo ezahlukeneyo zokusika isinyithi, izihlalo ezithwele i-CNC, i-CNC machining flanges, iinxalenye ze-arch, iindawo ezifakwe ngaphakathi, iinxalenye ezikhethekileyo, iinxalenye zeprofayili, amacandelo, izikwere, imichilo kunye nezinye iigrafu.

4.Ukusetyenziswa kwepleyiti yokunxiba

1) Umatshini wamandla obushushu obushushu: i-medium-speed coal coal cylinder liner, i-fan impeller socket, i-dust collector inlet flue, umbhobho wothuthu, i-bucket turbine liner, isahluli sombhobho, i-coal crusher liner, i-coal scuttle kunye ne-crusher Machine liner, isitshisi somlilo, ukuwa kwamalahle. i-hopper kunye ne-funnel liner, i-air preheater bracket protection tile, i-blade yesikhokelo sokwahlula.Amacandelo angentla awanayo imfuneko ephezulu kubunzima kunye nokumelana nokuxhatshazwa kweplate yensimbi engaguqukiyo, kunye nentsimbi yensimbi engaguqukiyo enobunzima be-6-10mm kwizinto eziphathekayo ze-NM360 / 400 zingasetyenziswa.

2) Iyadi yamalahle: isitya sokutya kunye ne-hopper, i-hopper, i-fan blades, ipleyiti ephantsi ye-pusher, umqokeleli wothuli lwe-cyclone, i-coke guide lining plate, i-ball mill lineng, i-drill stabilizer, i-screw feeder bell kunye nesihlalo sesiseko, umgca wangaphakathi we-kneader ibhakethi, i-ring feeder, ipleyiti yokulahla ilori ephantsi.Indawo yokusebenza yeyadi yamalahle inzima, kwaye kukho iimfuno ezithile zokumelana nokugqwala kunye nokumelana nokugqoka kweplate yensimbi engaguqukiyo.Kunconywa ukusebenzisa i-steel-resistant plate plate ye-NM400/450 HARDOX400 enobunzima be-8-26mm.

3) Iplanti yesamente: i-chute lining, i-end bushing, umqokeleli wothuli lwenkanyamba, iblade yokwahlula umgubo kunye neblayidi yesikhokelo, iblade yefeni kunye ne-lining, i-bucket lining, i-screw conveyor ezantsi ipleyiti, i-piping assembly, i-frit cooling plate liner, i-Conveyor liner.Ezi nxalenye nazo zifuna iipleyiti zetsimbi ezingagugiyo kunye nokumelana nokuguga okungcono kunye nokumelana nokugqwala, kunye neepleyiti zetsimbi ezingagugiyo ezenziwe nge-NM360/400 HARDOX400 ezinobunzima be-8-30mmd zingasetyenziswa.

4) Ukulayisha oomatshini: ukothula iipleyiti zemill chain, ii-hopper liners, iiblade zokubamba, iilori zokulahla ezizenzekelayo, imizimba yelori yokulahla.Oku kufuna iipleyiti zentsimbi ezinganxibiyo ezinokumelana nokunxiba okuphezulu kakhulu kunye nokuqina.Kucetyiswa ukuba kusetyenziswe iiplati zetsimbi ezingagugiyo kunye nezinto ze-NM500 HARDOX450/500 kunye nobukhulu be-25-45MM.

I-5) Umatshini wemigodi: ii-linings, ii-blades, i-conveyor linings kunye ne-baffles yamaminerali kunye nezityuli zamatye.Amalungu anjalo afuna ukuxhathisa okuphezulu kakhulu, kwaye izinto ezikhoyo zi-NM450/500 HARDOX450/500 iipleyiti zentsimbi ezixhathisayo ezinobunzima obuyi-10-30mm.

6) Oomatshini bokwakha: i-cement pusher tooth plate, i-concrete yokuxuba i-concrete, i-mixer lining plate, ipleyiti yokuqokelela uthuli, ipleyiti yokubumba umatshini wezitena.Kucetyiswa ukuba kusetyenziswe iipleyiti zetsimbi ezinqabileyo ezenziwe nge-NM360/400 ezinobunzima be-10-30mm.

7) Oomatshini bokwakha: ii-loaders, ii-bulldozers, iipleyiti zebhakethi ze-excavator, iipleyiti ze-side blade, iipleyiti ezisezantsi zebhakethi, ii-blades, i-rotary drilling rig drill rods.Olu hlobo lomatshini lufuna ipleyiti yentsimbi eyomeleleyo kwaye enganxibiyo enokumelana nokugruzuka okuphezulu kakhulu.Izinto ezikhoyo zi-NM500 HARDOX500/550/600 kunye nobukhulu be-20-60mm.

I-8) Umatshini we-Metallurgical: umatshini wokucoca intsimbi, ukuhambisa i-elbow, i-iron ore sintering machine liner, i-scraper liner.Kuba olu hlobo lomatshini lufuna ukumelana nobushushu obuphezulu kunye neepleyiti zentsimbi ezinganxibiyo.Ke ngoko, kuyacetyiswa ukuba usebenzise i-HARDOX600HARDOXHiTuf uthotho lweepleyiti zentsimbi ezinxibelelanayo.

9) Iipleyiti zentsimbi ezingagungqiyo zingasetyenziswa kwiisilinda zesanti, ii-blades, iiyadi ezahlukeneyo zempahla, oomatshini bokugcina kunye nezinye iindawo, izakhiwo zokuthwala, izakhiwo zamavili kaloliwe, imiqulu, njl.

Nxiba ipleyiti ekwaziyo ukumelana, ipleyiti yokunxiba, nxiba ipleyiti yentsimbi

Ukunxiba ipleyiti yentsimbi enganyangekiyo ibhekisa kwiimveliso zepleyiti ezikhethekileyo ezisetyenziswa kwindawo enkulu yokunxiba imeko.Ipleyiti exhathisayo yentsimbi inokumelana ne-abrasion ephezulu kunye nokusebenza kakuhle kwempembelelo.Inokunqunyulwa, igobe, idityaniswe, njl njl. Inokudibaniswa nezinye izakhiwo nge-welding, iplagi ye-welding kunye ne-bolt uxhumano, ineempawu zokulondoloza ixesha kwaye zilungele kwinkqubo yokugcinwa.

Ngoku isetyenziswa ngokubanzi kwi-metallurgy, amalahle, isamente, umbane, iglasi, imigodi, izinto zokwakha, izitena kunye namanye amashishini.Xa ithelekiswa nezinye izinto, ineendleko eziphezulu kwaye iye yathandwa ngamashishini amaninzi kunye nabavelisi.

Uluhlu lobungakanani :

Ukutyeba 3-120mm Ububanzi : 1000-4200mm Ubude : 3000-12000mm

Itheyibhile yokuthelekisa iNsimbi ekwaziyo ukunxiba

| GB | WUYANG | JFE | I-SUMITOMO | I-DILLIDUR | SSAB | HBW | Ubume bokuhanjiswa |

| NM360 | WNM360 | JFE-EH360A | K340 | —- | —- | 360 | Q+T |

| NM400 | WNM400 | JFE-EH400A | K400 | 400V | I-HADOX400 | 400 | Q+T |

| NM450 | WNM450 | JFE-EH450A | K450 | 450V | I-HADOX450 | 450 | Q+T |

| NM500 | WNM500 | JFE-EH500A | K500 | 500V | HARDOX500 | 500 | Q+T |

| NM550 | WNM550 | —- | —- | —- | I-HADOX550 | 550 | Q+T |

| NM600 | WNM600 | —- | —- | —- | I-HADOX600 | 600 | Q+T |